Company tel:+86-379-63184520

Contact number:+86-15937921751

Postcode:471000

Email:info@yuxindiamond.com

Address:3-1-508 Luoyang National University Science Park, No. 2 Penglai Road, Jianxi District, Luoyang, China 471000

Diamond Can Turn Flexible When Made Into Ultrafine Needles

Diamond is well-known as the strongest of all natural materials, and with that strength comes another tightly linked property: brittleness. But now, an international team of researchers from MIT, Hong Kong, Singapore, and Korea has found that when grown in extremely tiny, needle-like shapes, diamond can bend and stretch, much like rubber, and snap back to its original shape.

The results, the researchers say, could open the door to a variety of diamond-based devices for applications such as sensing, data storage, actuation, biocompatible in vivo imaging, optoelectronics, and drug delivery. For example, diamond has been explored as a possible biocompatible carrier for delivering drugs into cancer cells.

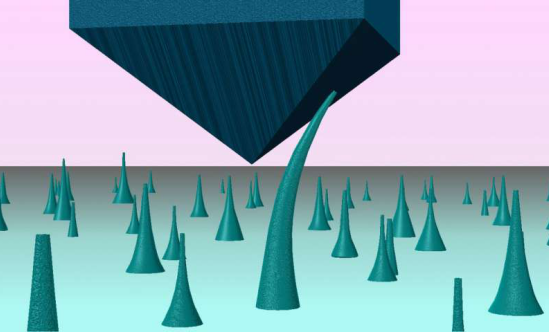

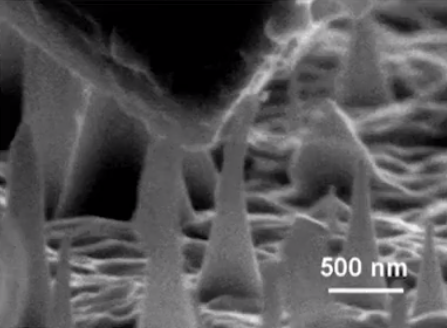

The team showed that the narrow diamond needles, similar in shape to the rubber tips on the end of some toothbrushes but just a few hundred nanometers (billionths of a meter) across, could flex and stretch by as much as 9 percent without breaking, then return to their original configuration, Dao says.

Ordinary diamond in bulk form, Bernoulli says, has a limit of well below 1 percent stretch. "It was very surprising to see the amount of elastic deformation the nanoscale diamond could sustain," he says.

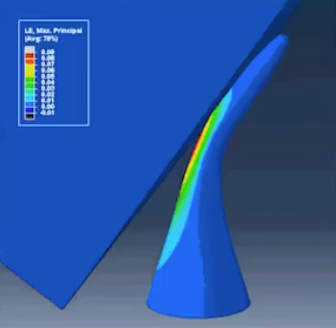

"We developed a unique nanomechanical approach to precisely control and quantify the ultralarge elastic strain distributed in the nanodiamond samples," says Yang Lu, senior co-author and associate professor of mechanical and biomedical engineering at CUHK. Putting crystalline materials such as diamond under ultralarge elastic strains, as happens when these pieces flex, can change their mechanical properties as well as thermal, optical, magnetic, electrical, electronic, and chemical reaction properties in significant ways, and could be used to design materials for specific applications through "elastic strain engineering," the team says.

The team measured the bending of the diamond needles, which were grown through a chemical vapor deposition process and then etched to their final shape, by observing them in a scanning electron microscope while pressing down on the needles with a standard nanoindenter diamond tip (essentially the corner of a cube). Following the experimental tests using this system, the team did many detailed simulations to interpret the results and was able to determine precisely how much stress and strain the diamond needles could sustain," he says.

The researchers also developed a computer model of the nonlinear elastic deformation for the actual geometry of the diamond needle, and found that the maximum tensile strain of the nanoscale diamond was as high as 9 percent. The computer model also predicted that the corresponding maximum local stress was close to the known ideal tensile strength of diamond—i.e. the theoretical limit achievable by defect-free diamond.

When the entire diamond needle was made of one crystal, failure occurred at a tensile strain as high as 9 percent. Until this critical level was reached, the deformation could be completely reversed if the probe was retracted from the needle and the specimen was unloaded. If the tiny needle was made of many grains of diamond, the team showed that they could still achieve unusually large strains. However, the maximum strain achieved by the polycrystalline diamond needle was less than one-half that of the single crystalline diamond needle.

With the improvement of CVD synthesis technology, through the adoption of gas raw material (hydrogen, methane), we get the completely transparent and colorless large size diamond single crystal under less than one air pressure, the temperature of 800-1200 ℃ by epitaxial growth way, its composition, hardness, density, etc. are basically identical with natural diamond, but the price is much lower than that of natural diamond; different from the method of high temperature and high pressure (HTHP), CVD Lab-grown synthetic technique does not need to use the catalyst, and puts an end to forming metal inclusions, cracks, holes, etc. in the production.

Features: after polishing, the clarity is commonly VVS and above level, color chromaticity of D-J.

We can provide raw diamond at carat level.