Company tel:+86-379-63184520

Contact number:+86-15937921751

Postcode:471000

Email:info@yuxindiamond.com

Address:3-1-508 Luoyang National University Science Park, No. 2 Penglai Road, Jianxi District, Luoyang, China 471000

Introduction of Equipment for Preparing CVD Diamond by DC Arc Plasma Jet Method

Introduction of DC Arc Plasma Jet equipment

The DC Arc plasma torch is usually composed of a rod-like cathode and a cylindrical anode surrounding the cathode. An appropriate DC voltage is applied to the cathode and anode, and the gas is ignited by a gas breakdown before passing through the anode and the anode. The gas is heated by the arc to a very high temperature [at the anode outlet (nozzle) up to 4000 ~ 6000K, or even higher], after the rapid expansion of the nozzle from the plasma torch out of the road to form a high temperature, high speed plasma jet. The substrate must be forced to cool with water, usually placed below the plasma torch. A mixed gas of hydrogen, argon and methane is usually used as the raw material gas. The role of argon is easy to ignite the arc and maintain the arc discharge, hydrogen and methane are the diamond film deposition common raw materials gas. It is also possible to use hydrogen only, and it is believed that hydrogen plasma is more advantageous than argon-hydrogen plasma because argon does not seem to have a direct effect on the diamond film deposition process, and it is not necessary to give extra energy to heat and ionize it. In addition to methane, other carbon sources can be used. Mo is generally used as a substrate, due to high temperature high-speed air flow caused by a very serious thermal shock, the substrate must be forced water cooling.

A schematic diagram for a simple experience of DC Arc Plasma Jet CVD equipment

DC arc plasma jet CVD is a typical diamond film high-speed deposition method, so far still maintained 930μm / h of the highest deposition rate of diamond film. Unlike microwave plasma CVD (high electron temperature, low gas temperature), arc plasma is close to the equilibrium state of the thermal plasma, electronic temperature and gas temperature are high, the plasma ionization is sufficient to provide a very high Atomic hydrogen concentration, and thus can take into account the deposition rate and the quality of diamond film. Therefore, DC arc plasma jet CVD is considered to be the most promising application of diamond film preparation technology in hot-filament CVD, microwave plasma CVD, combustion flame deposition and DC arc plasma jet CVD four diamond film deposition methods. However, the early DC arc plasma CVD based on industrial ultrasonic torch technology has a small deposition area and poor uniformity, and it has not been able to meet the requirements of industrial production until the early 20th century. China's high-power DC arc plasma jet CVD technology based on rotary arc and gas circulation technology supported by the "863" program is the only technology at home and abroad that has been successfully used for the industrial production of high quality diamond self-supporting films.

The parameters range and advantages and disadvantages of the DC Arc plasma jet CVD

30-50KW of the DC preparation equipment, after more than 10 years of deposition, improvement, process accumulation, and now the preparation of the diamond film products can achieve the following technical indicators: three point bending strength Rf can reach 400MPa, line wear ratio of up to 500,000; 8-12μm infrared band transmittance of 70%; radial thermal conductivity of up to 19w /cm.k; axial thermal conductivity of 21w /cm.k; antioxidant capacity of 780 ℃ to heat 180s after 8-12μm band transmittance decreased <3%; microwave dielectric constant 5.2GH tgδ = 8 × 10-4 close to the international 10-5. Anti-laser damage: YAG-6.7J/cm2-pulse 10ns; CO2-115~226KW / cm2-light speed of 0.5mm when the damage value of 1.15 × 106W/cm2. Non-uniformity of film thickness is < 8%. The minimum thickness is 0.10 mm. Degree of finish is up to Ra0.012.

Equipment composition

The device consists of the following major systems:

Vacuum deposition chamber;

Vacuum acquisition system;

Exhaust and growth pressure regulating systems;

Deposition unit system;

Deposition power supply;

Vacuum pipes, accessories, main frame;

Electrical automation control system;

Airway, waterway system;

Vacuum measurement system, temperature, pressure, flow measurement and control system.

Advantages of DC Arc Plasma vacuum equipment

Gas flow controllable

Simple gas material

High quality CVD diamond

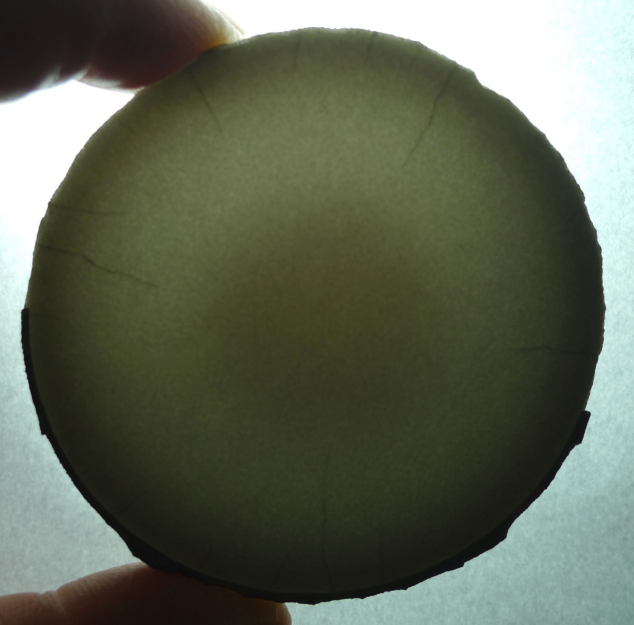

Products display

DC Arc Plasma CVD Diamond film

High power laser window

CVD diamond dressing tools