Company tel:+86-379-63184520

Contact number:+86-15937921751

Postcode:471000

Email:info@yuxindiamond.com

Address:3-1-508 Luoyang National University Science Park, No. 2 Penglai Road, Jianxi District, Luoyang, China 471000

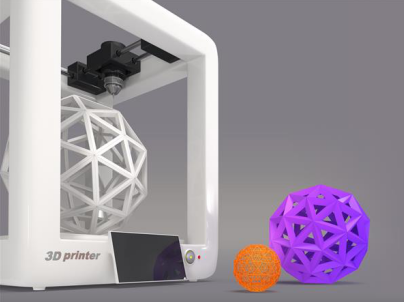

Diamonds Now a 3D Printer's Best Friend

Finnish nanodiamond manufacturer Carbodeon and Dutch 3D printing specialist Tiamet 3D have announced an exciting 3D printing innovation: the first nanodiamond-enhanced FDM 3D printer filaments for additive manufacturing.

Diamonds, solid chunks of carbon that have been coveted by humans for centuries, are many things. Diamonds are forever, diamonds are a girl’s best friend, and diamonds are now—surprisingly—an FDM 3D printing material.

Using a jointly patented technology, Finnish nanodiamond manufacturer Carbodeon and Dutch 3D printing specialist Tiamet 3D have developed the first nanodiamond-enhanced filaments for 3D printing.

Nanodiamonds, as the name suggests, are tiny diamond particles with a dimension of around five nanometers. They’re far too small to see, but—in certain quantities—still provide many of the mechanical properties of super-hard diamonds.

The two companies making these nanodiamond 3D printer filaments say the presence of the tiny diamond particles within polymers significantly improves the mechanical and thermal properties of 3D printed items, so it’s exciting news not just for those looking to bling up their 3D prints, but also those who want to strengthen them.

“By joining forces, we’ve already developed filaments with a 100 percent increase in tensile strength, improved printability, and better thermal properties,” said Reid Larson, CEO of Tiamet 3D. “Printing also runs more quickly and more reliably with the addition of Carbodeon polymer-tailored nanodiamonds.”

These nanodiamond 3D printer filaments, with their improved performance, purportedly have potential in many manufacturing environments—especially in the electronics, automotive, and aerospace industries.

There are other benefits too. The companies say that, as well as improving the thermal management, conductivity, and tensile strength of the base polymer, nanodiamonds can increase the glass transition temperature of a 3D printed product or component to achieve more robust and reliable polymer products. These diamond-boosted 3D printed products are therefore suitable for “more challenging environments.”

So what kind of filaments will these nanodiamonds be going into? Carbodeon and Tiamet 3D say their first 3D printing material will be a nanodiamond PLA for FDM 3D printers, but higher-performance thermoplastics will soon follow.

The companies have signed a strategic partnership agreement to develop new 3D printer filaments together, which will involve Carbodeon supplying its nanodiamond materials to Tiamet 3D.

“Nanodiamonds offer the potential to make 3D printed components that perform as well as or better than comparable injection moulded components, but with massive cost reductions and production speed improvements, especially for prototype, on-demand and short run production,” said Carbodeon CEO Dr. Vesa Myllymäki, who added that “product development partnerships with innovative companies like Tiamet 3D are a key part of Carbodeon’s global growth strategy.”

No word yet on the cost of these nanodiamond 3D printing filaments, but the early buyers of the 3D printing material might try fabricating this 3D printed replica of Meghan Markle’s engagement ring!

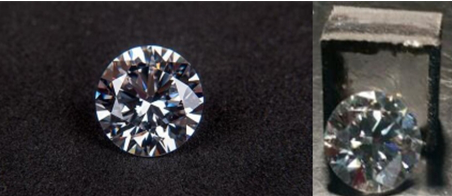

With the improvement of CVD synthesis technology, through the adoption of gas raw material (hydrogen, methane), we get the completely transparent and colorless large size diamond single crystal under less than one air pressure, the temperature of 800-1200 ℃ by epitaxial growth way, its composition, hardness, density, etc. are basically identical with natural diamond, but the price is much lower than that of natural diamond; different from the method of high temperature and high pressure (HTHP), CVD Lab-grown synthetic technique does not need to use the catalyst, and puts an end to forming metal inclusions, cracks, holes, etc. in the production.

Features: after polishing, the clarity is commonly VVS and above level, color chromaticity of D-J.

We can provide raw diamond at carat level.