Company tel:+86-379-63184520

Contact number:+86-15937921751

Postcode:471000

Email:info@yuxindiamond.com

Address:3-1-508 Luoyang National University Science Park, No. 2 Penglai Road, Jianxi District, Luoyang, China 471000

Diamonds' Flaws Hold Promise for New Technologies

Despite their charm and allure, diamonds are rarely perfect. They have tiny defects that, to assistant professor Nathalie de Leon, make them ever so appealing. These atom-sized mistakes have enormous potential in technologies for high-resolution imaging and secure communication lines.

"Historically, people called these defects 'color centers' because when you shine light on a diamond you see a bunch of pretty colors come back," said de Leon, who is appointed in the Department of Electrical Engineering. She wants to harness the properties of these defects to image molecules and proteins.

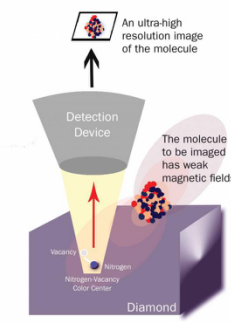

A diamond is a tightly knit lattice of carbon atoms. By kicking out one of the carbons and adding a nitrogen atom nearby, the researchers can create a defectknown as a "nitrogen-vacancy color center." The nitrogen atom and the dangling bonds around the missing carbon atom form a sort of molecule within a small area of the diamond lattice. This area of the diamond acts like a verdant oasis in the middle of a desert, displaying very different properties than the rest of the material.

De Leon is working on using a nitrogen-vacancy color center near the surface of a diamond to capture images of molecules. The approach takes advantage of a property of the defect known as "spin," which is analogous to the momentum of a spinning top. These spins interact with the molecule's magnetic field, which varies from one part of the molecule to another. The signals from these interactions can be collected and processed to make an image that is very high in spatial resolution—high enough to image a single molecule of DNA.

For this to work, the only signal emanating from the surface of the diamond has to be the one from the color center. But that's a difficult feat, as the moment the diamond is exposed to air, its surface atoms latch onto molecules floating around. Further, cutting or polishing one of the hardest materials in the world brings other unwanted defects to the surface.

All of these extra signals cloud the measurement. In fact, when researchers try to remove the unwanted defects from an initial polish, they inadvertently create more defects that again need to be removed. "You have a mouse problem, so you release the cats, and you have a cat problem, so you release the dogs. It just keeps going," de Leon said. Finding ways to improve the diamond surface is an ongoing area of research, and de Leon is hopeful that a combination of chemical treatments and a high-purity environment might do the trick.

olor centers for communication

While these color centers may eventually serve as sensors for biological applications, they can also be the basis for new communication networks—ones that would make eavesdropping impossible.

In quantum communication systems, an eavesdropper would not be able to read a message without immediately altering its state, thus exposing the attempt to pry into the message. It would also be impossible to copy a quantum message.

Making the signals robust enough to travel long distances has stalled the development of quantum technologies, de Leon said. She is working to build a "repeater" that can boost the signal and forward it through a cable until it reaches its destination. This would require a material capable of making quantum memories. The material would store and recover the original signal to propel the signal through the cables.

"What we are looking for is the heart of this quantum repeater," de Leon said. Her team recently discovered a candidate for such a heart: a defect within a diamond in the form of a large silicon atom hovering between two holes in the lattice.

It turns out this defect has very good charge and light properties, two necessary ingredients for a good quantum memory. The defect is also more resilient to interference by electric fields from the environment than other approaches.

With the improvement of CVD synthesis technology, through the adoption of gas raw material (hydrogen, methane), we get the completely transparent and colorless large size diamond single crystal under less than one air pressure, the temperature of 800-1200 ℃ by epitaxial growth way, its composition, hardness, density, etc. are basically identical with natural diamond, but the price is much lower than that of natural diamond; different from the method of high temperature and high pressure (HTHP), CVD artificial synthetic technique does not need to use the catalyst, and puts an end to forming metal inclusions, cracks, holes, etc. in the production.

Features: after polishing, the clarity is commonly VVS and above level, color chromaticity of D-J.

We can provide raw diamond at carat level.