Company tel:+86-379-63184520

Contact number:+86-15937921751

Postcode:471000

Email:info@yuxindiamond.com

Address:3-1-508 Luoyang National University Science Park, No. 2 Penglai Road, Jianxi District, Luoyang, China 471000

Using Correlated Photons To Enhance X-ray Imaging

A team of researchers at Bar-Ilan University has found a way to use correlated photons to make sharper X-ray images.In their paper published in the journal Physical Review Letters,the group describes their process and suggest ways it could be used in commercial applications.

An X-ray machine creates images of bones inside the body by firing X-rays(high energy photons)at the injured site and using the photons to create an image on film.Those that pass through appear dark—those that cannot pass through result in white areas on the film.But such films are usually hazy because of background radiation.In this new effort,the researchers have found a way to use correlated photons to improve the images.

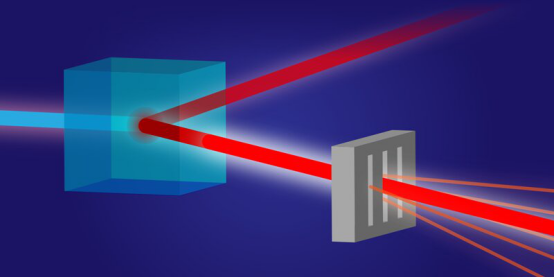

The new method involved firing an X-ray beam at a diamond,forcing the beam to split into two.Splitting the beam involved splitting each of the single photons in the beam into two correlated photons in the two newly created beams.The researchers directed one of the new beams at a target to be X-rayed—a metal strip with slits.A sensor was placed behind the target to capture photons,as in normal X-ray machines.The other beam was aimed directly at a detector.Then,because the pairs of photons were correlated,the researchers were able to determine which photons fired at the target were from the original beam as opposed to background noise.This allowed for using only those photons from the original beam to make the X-ray image.

The researchers report that images created with their new method had approximately 1000 times less background noise,making them significantly sharper.They note that their method currently works only with extremely strong X-ray beams,and would thus not work for medical applications.But they also note that their technique could prove useful for scientists to better understand quantum mechanics.They plan to continue their work,looking next to determine whether the photons produced by their technique were entangled.

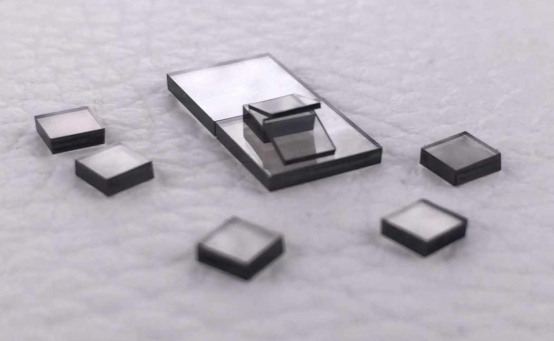

Luoyang Yuxin Diamond Co.,Ltd’s CVD single crystal diamond is manufactured by Microwave Plasma Chemical Vapor Deposition.With good wear resistance,thermal conductivity and compressive resistance,high hardness and strength,low friction coefficient,excellent corrosion resistance and chemical stability,it can be sharpened into very sharp blade,and it is considered to be the most ideal ultra-precision cutting tool material,which occupies an important position and is widely used in the mechanical processing field especially the ultra precision processing field.

Features:used in ultra precision cutting tools,especially processing non-ferrous metal materials,such as aluminum(alloy),copper,high polymer materials(MMCs),carbon fiber reinforced plastics(CFPs)Parts surface can be the mirror effect,and its surface roughness can reach below Ra-0.1μm.